Get a Quote

The lead-acid battery powered 20 Tons Track Turning Steel Pipe Transfer Cart designed by Henan Remarkable for Croatian customer has the functions of forward, backward, and turning. According to the customer's usage requirements, we have designed a turning function for this heavy-duty track transfer vehicle that is suitable for the customer's on-site curved track. It is operated by a remote control and an on-board handle, and is also equipped with a touch screen to monitor the vehicle's operating status at any time. If there is an obstacle in the car, it will be displayed on the touch screen.

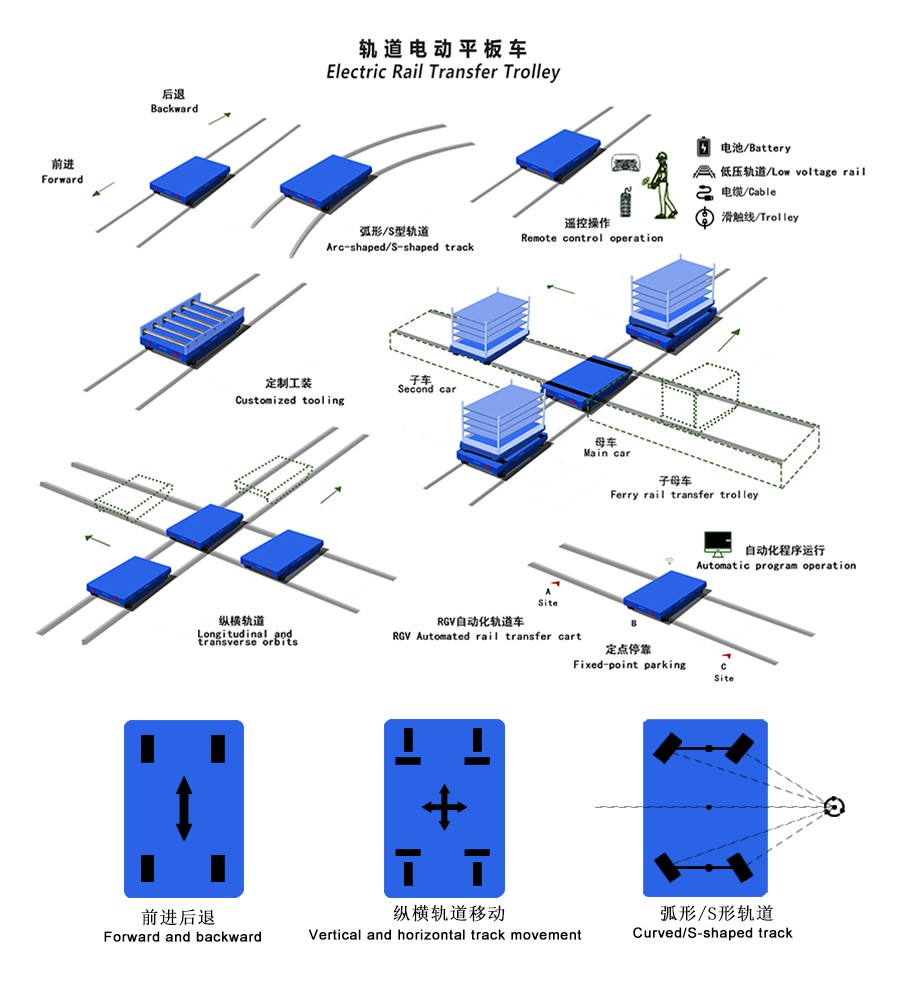

The advantages of track turning transfer cart mainly include the following:

-Stable operation: Traveling along a fixed track, constrained by the track when turning, the trajectory is precise, not prone to deviation, and can ensure the smoothness of the operation process.

-Easy to operate: Usually only simple operations such as starting, stopping, and speed need to be controlled. The turning action is determined by the track design, and the technical requirements for the operator are relatively low.

-High safety: The track restricts the travel path, reducing the risks of collisions, derailments, etc. caused by human error or external factors, especially suitable for safe transportation in specific areas.

-High efficiency: It can circulate on a planned track, suitable for repetitive and regular transportation tasks, and can improve the efficiency of material or personnel transportation.

-Simple structure: mainly composed of the vehicle body and track, the structure is relatively simple, the maintenance and upkeep costs are low, and the service life is long.

The track turning transfer trolley is suitable for the following scenarios:

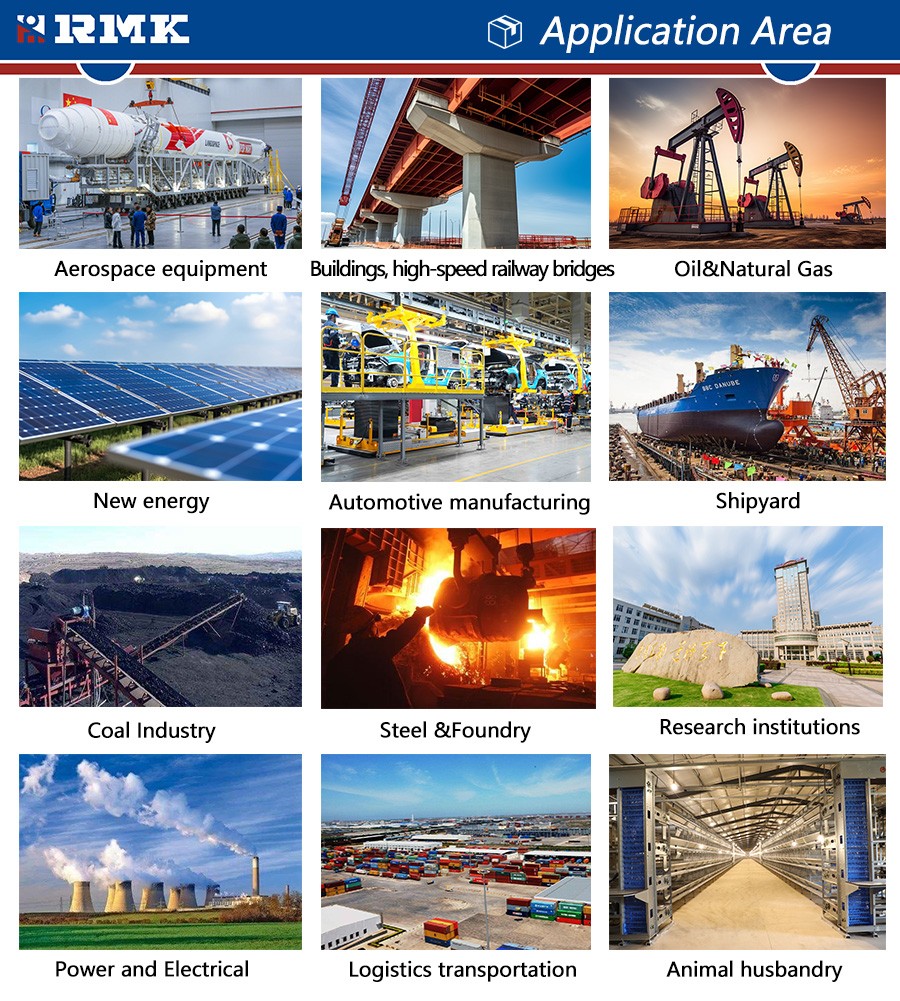

-Factory workshop: Flexible track routes can be designed based on workshop layout and production processes for transporting machined parts, finished products, stamped parts, castings, etc

-Warehouse logistics: capable of turning and transporting goods within the warehouse

-Port terminal: used for transferring goods and containers

-Circular production line: suitable for operation on a circular production line, transporting workpieces or materials in sequence to various processing stations to ensure the continuity and stability of the production process.

-Engineering homework: In some construction scenarios, such as bridge construction, construction sites, etc., it can be used to transport large components, concrete and other heavy objects, achieving precise transportation and positioning.

This lead-acid battery rail transporter has a functional design that is quite in line with actual needs. Lead acid batteries provide stable power and are suitable for heavy-duty scenarios. The combination of forward, backward, and turning functions with curved tracks enables flexible transportation of goods at customer sites, making it suitable for precise positioning in places such as factory workshops and warehousing logistics.

The dual operation mode of remote control and on-board handle is quite convenient, and workers can both remotely control and manually operate from the side of the car, so the safety should be good. The design of touch screen monitoring of operating status is very practical. If the car encounters obstacles, it can display them in real time, which facilitates timely troubleshooting and reduces downtime. I feel that this heavy-duty rail car should be quite efficient in transporting containers at port terminals or transporting workpieces on circular production lines, as its turning function can adapt to different track layouts.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.