Get a Quote

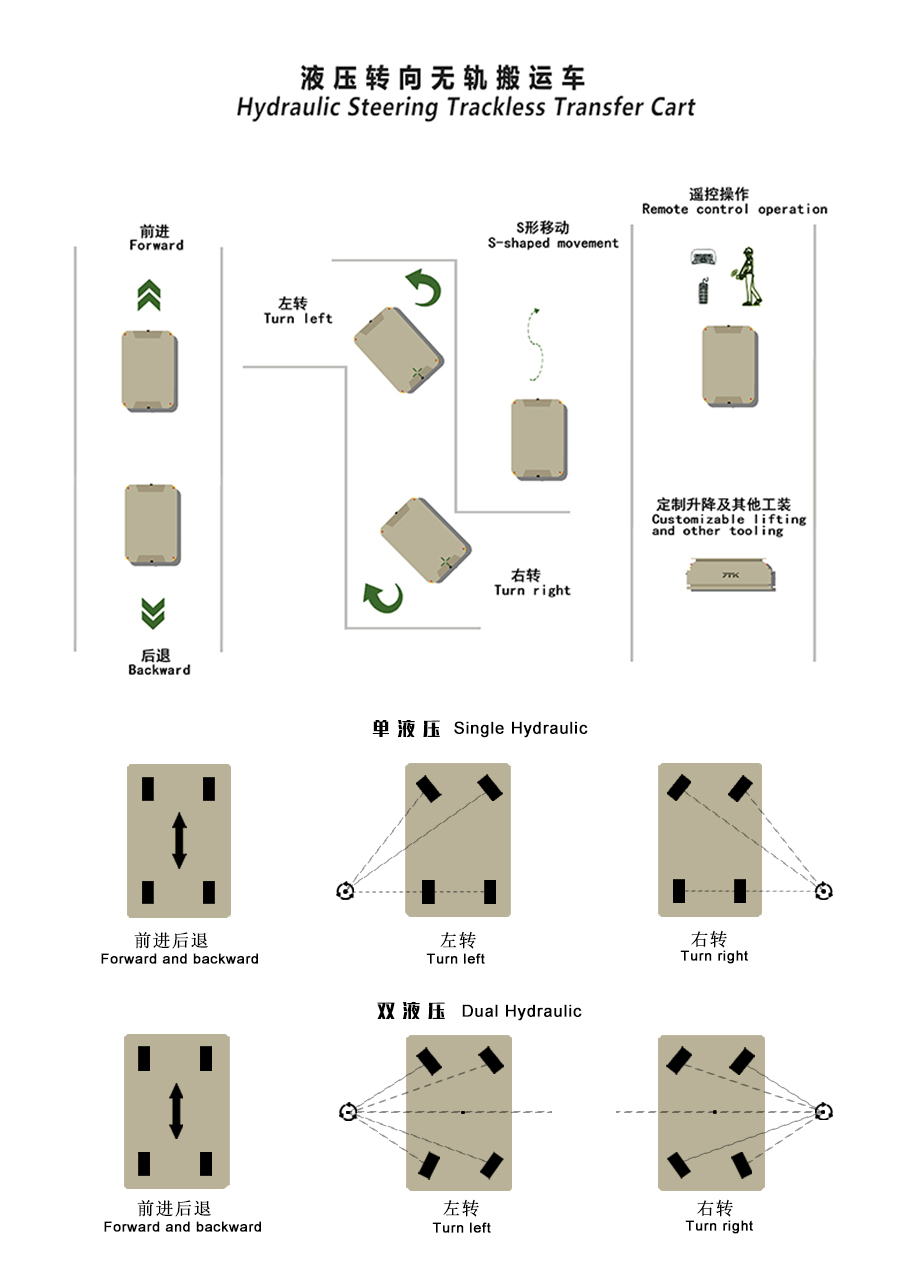

Henan Remarkable customizes the 40T Dual Hydraulic Steering Transformer Transport Trolley for One Turkey customer, the battery transfer cart's table size is too large of 13m length and 3m width, so in order to make the cart more safely and smoothly in moving and turning, we design the cart with dual hydraulic steering, it can reduce the turning radius.The customer outside workshop ground is rough, so we choose the press fit solid rubber wheels for the heavy load transport platform. Besides, Henan Remarkable can also design and produce omni-directional transfer cart, hydraulic lifting transfer trolleys and AGV.

Main technical specifications about heavy duty transporter:

1.Load capacity:1-300T

2.Table size: it can be customized according to customer's requirements and needs

3.Power supply mode: lead acid battery or lithium battery

4.Operate mode: wirelss remote control+wire hand pendant

5.Speed:0-50m/min can be customized

6.Protective devices: alarm light, emergency stop button, laser scanning sensor

Heavy duty hydraulic steering trackless transfer vehicles are mainly suitable for the heavy industry sector, with core application industries including:

1. Automotive manufacturing industry: used for workshop transportation of stamping parts, engine assemblies, and complete vehicles;

2. Construction machinery industry: handling parts and finished equipment for large excavators and cranes;

3. Metallurgical industry: transporting heavy materials such as steel coils, steel billets, and non-ferrous metal ingots;

4. Energy industry: transportation of large equipment in the fields of nuclear power and wind power (such as wind turbine hubs and nuclear pressure vessels);

5. Port and logistics industry: heavy cargo loading and unloading and short distance transportation at ports and large warehouses;

6. Aerospace industry: high-precision transportation of aircraft components and aerospace equipment.

The flexible maneuverability and heavy load capacity of its hydraulic steering system can be well adapted to industrial scenarios that require frequent adjustment of direction and handling of large tonnage items

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.