Get a Quote

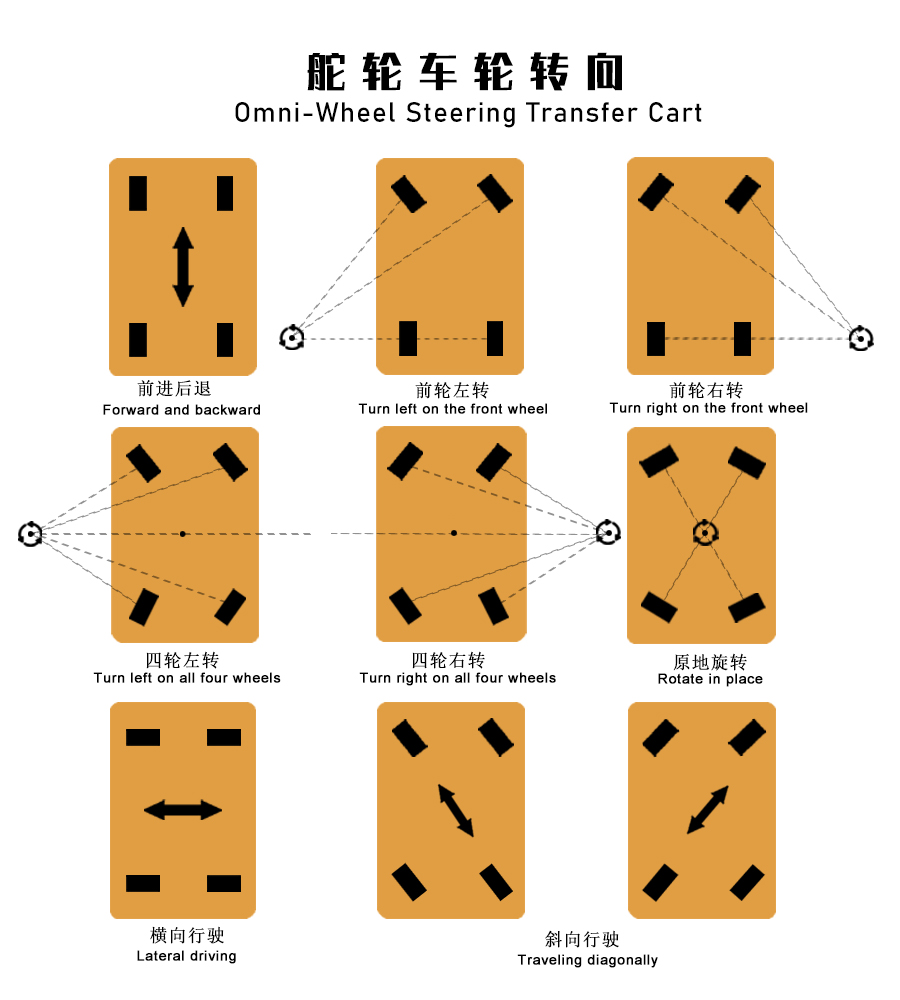

Henan Remarkable specially designed this 5 Tons Omni-directional Transfer Cart with roller device for our customers. The transfer trolley can achieve precise docking with customers' production lines or production equipment and efficiently transport materials.The battery powered transport cart supports fully automated operation and features a crab-like omnidirectional movement trajectory.

Powered by a lithium battery, this heavy-duty trackless platform is equipped with a standard communication protocol, which can accurately transmit signals such as low battery and charging requests. The transporter will automatically move to the nearest charging station for autonomous charging.

Main technical specifications:

1.Load capacity: 5 tons

2.Table size: 3000*2000*700mm

3.Power supply mode: Lithium battery

4.Protective devices: Alarm light, emergency stop button

5.Operate mode: Hand pedant + wireless remote control

6.Other requirements: roller design

The core advantages of omnidirectional mobile railless vehicles (omnidirectional AGV, Mecanum wheel/steering wheel omnidirectional vehicle) are zero turning radius, lateral/oblique movement, precise micro movement, no need for ground magnetic strips/tracks, suitable for small spaces, high precision requirements, heavy loads, and flexible production line scenarios. The mainstream application areas are as follows:

1、 Intelligent Manufacturing&Factory Logistics (Core)

-Automobile whole vehicle/parts: chassis assembly on the final assembly line, engine/battery pack transportation, material distribution in the welding/painting workshop

-Construction machinery/heavy equipment: heavy-duty transportation of large structural components, frames, and boxes

-3C/Electronics/Semiconductors: SMT materials, precision components, cleanroom light load high-precision handling

2、 New energy industry

-Power battery: cell/module/Pack line transportation, chemical conversion/capacity division process handling

-Photovoltaic/Energy Storage: Handling of Photovoltaic Modules, Energy Storage Battery Cabinets, and Large Cell Boxes

-New energy vehicle battery swapping/assembly: battery pack lifting, assembly, workstation docking

3、 Warehouse Logistics&Flexible Delivery

-Intelligent warehousing: rack to workstation, box/pallet level trackless handling

-Internal closed-loop logistics: cross workshop material transfer, replacing traditional forklifts/oxen

4、 Aerospace&Rail Transit (High Precision+Heavy Load)

-Aviation: aircraft fuselage/wing component docking, engine assembly and transportation, tooling relocation

-Rail Transit: Metro/High Speed Rail Car Assembly, Bogie, Precise Vehicle Displacement

5、 Special Scene

-Port/Terminal: Container assisted alignment, on-site transportation of heavy spare parts

-Military/special equipment: precision equipment assembly, safe transportation of heavy components

6、 Key features suitable for selection

-Narrow venue access and limited turning space

-Need for lateral translation, in-situ rotation, and precise docking (± 1mm level)

-Flexible and versatile routes, no need to lay magnetic strips/QR codes

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.