Get a Quote

As an innovative equipment for internal material handling in factories, omnidirectional transfer trolley inject unprecedented flexibility into industrial scenarios based on manual remote control operations.

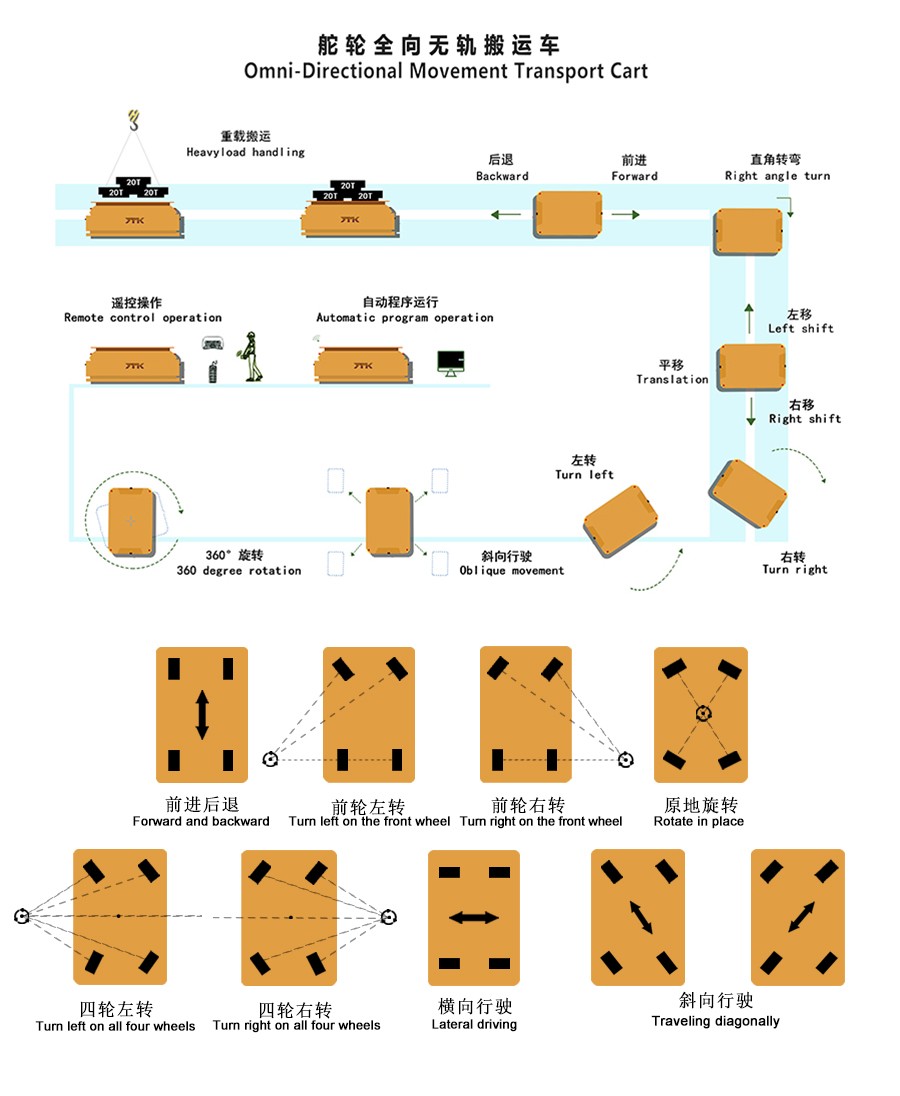

The remote control in the hands of the workers is like a precise "baton", which can easily drive the transfer trolley to complete diverse motion commands: whether it is forward and backward in a straight line, lateral translation that maintains the body posture like a crab, or oblique shuttle and 360 degree stationary rotation, it can be accurately achieved in milliseconds.

This characteristic of breaking through the traditional movement trajectory limitations of handling equipment allows it to handle workshops filled with machinery and equipment, narrow channel corners, or storage areas filled with materials with ease, completely solving the pain points of large turning radius and time-consuming attitude adjustment of traditional forklifts, ground oxen, and other equipment.

Omnidirectional transport vehicles are not limited to manual operation as "tools", but have strong potential for upgrading to automation, providing a key pivot for the intelligent transformation of factories.

By installing devices such as LiDAR and visual sensors, it can construct real-time environmental maps, autonomously plan the optimal path, and avoid sudden obstacles;

After connecting to the MES (Manufacturing Execution System) of the factory, it can automatically receive production scheduling instructions. For example, in the automotive parts workshop, it can transfer the engine cylinder block from the forging area to the assembly line according to the work order, without the need for manual intervention throughout the entire process;

If equipped with a robotic arm or automatic lifting device, it can also achieve automatic loading and unloading of materials, forming a closed-loop process of "picking, transporting, and placing".

This transformation can not only free workers from repetitive handling work, but also improve logistics turnover efficiency by more than 30% through 24-hour uninterrupted operation, especially suitable for modern factories with flexible production lines and customized production as the main focus.

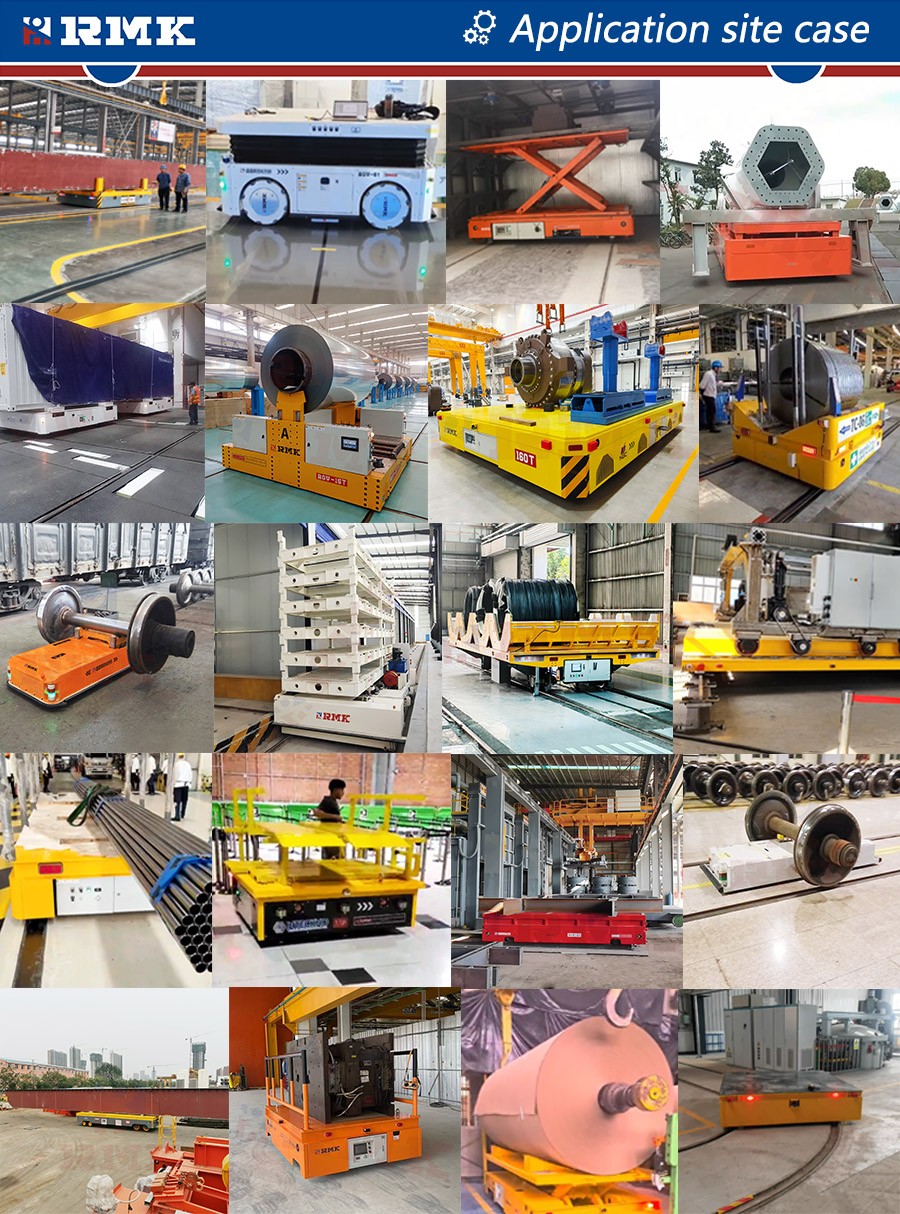

From the perspective of application scenarios, the value of omnidirectional transport vehicles is highlighted in various factory environments: in the clean room of electronic factories, its low-noise and dust-free design combined with precise motion can avoid interference with the production environment of precision chips;

In heavy machinery factories, the combination of strong load-bearing capacity and flexible steering allows for easy handling of machine tool components weighing several tons;

In the sorting center of e-commerce warehousing, automated omnidirectional vehicles can form an intelligent handling matrix to efficiently complete cross regional transfer of goods based on order information.

It can be said that whether it is short distance transportation within a single workshop or material scheduling across factory areas, omnidirectional transport vehicles can become a key engine for improving factory logistics efficiency with their core advantage of "flexibility and variability".

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.