Get a Quote

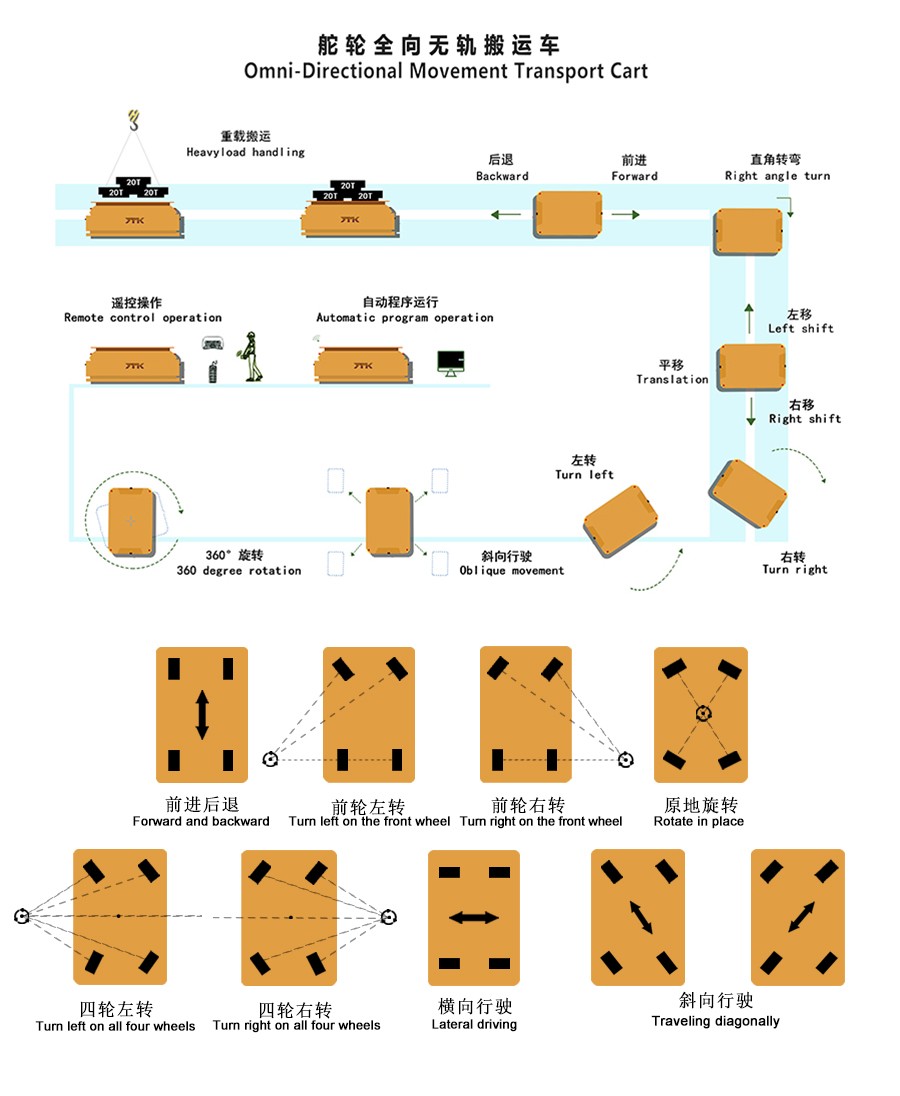

Due to the fact that the battery powered transfer trolley will be transporting goods in narrow spaces for easy turning, we have designed an omnidirectional movement function. This Heavy Duty 10 Tons Transformer Multi Move Transfer Trolley can move forward, backward, left turn, right turn, turn while walking, rotate 360 degrees, move horizontally and vertically, and move diagonally, ensuring smooth and flexible operation. In addition, some protective measures have been installed on the transfer carts, such as sound and light alarm lights, emergency stop buttons, and laser obstacle avoidance sensors designed and installed on all four sides of the transport platform to prevent improper operation by workers, damage to the trailer or other equipment in the workshop, or collision with people.

Easy to operate

-Remote control operation: Generally, it can be operated through remote control or wire control, which is convenient and fast, reducing the labor intensity of operators.

High security performance

-Multiple safety protection devices: usually equipped with safety protection functions such as collision sensors, emergency stop buttons, etc., to prevent collisions or other accidents during vehicle operation.

Widely used

-Manufacturing industry: In stamping workshops in industries such as automobile manufacturing and home appliance manufacturing, it is used for mold replacement and transportation, which can improve production efficiency and reduce labor costs.

Main technical specification about multi movement transfer trolley:

Load capacity: 10 tons

Table size: 3000*2000*600mm

Power supply mode: lithium battery

Move way: forward,backward, rotate 360 degrees, turning while in moving without any stop, Vertical and horizontal movement

Brake: Electromagnetic brake

Operate mode: hand pendant, remote control,Laser navigation and magnetic navigation(optional)

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

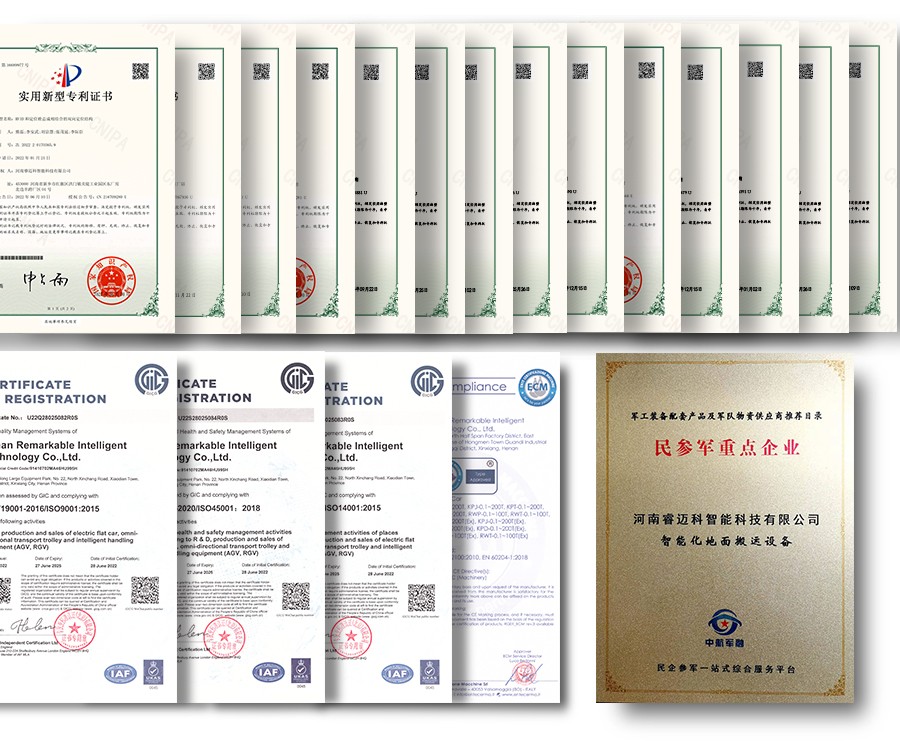

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.