Get a Quote

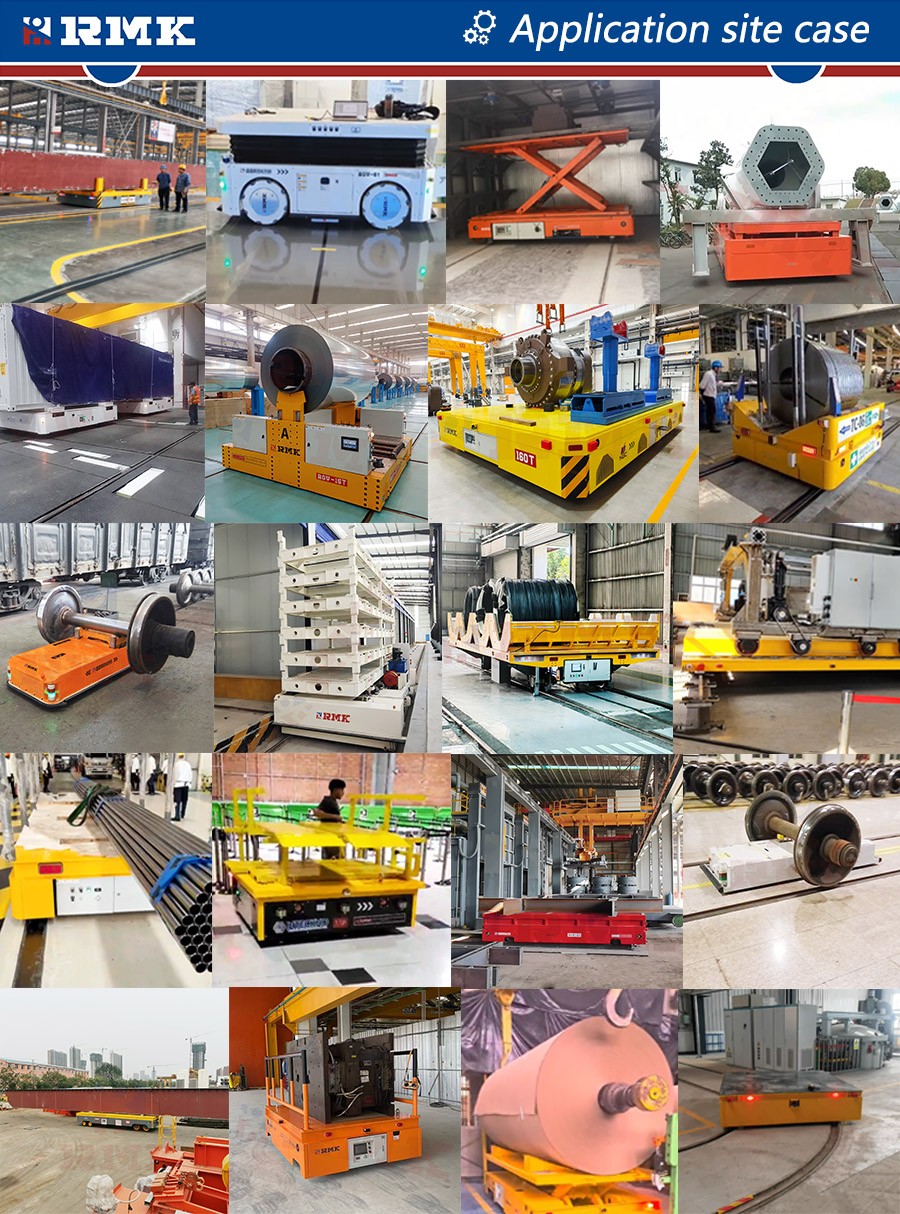

Heavy-duty electric transfer carts are electric equipment used for handling heavy cargo, widely applied in factories, warehouses, ports, construction sites, and other scenarios. They can achieve a transportation load capacity of up to 1,000 tons, with electric drive systems using large-capacity lithium batteries/lead-acid batteries. Some models support fast charging or battery swapping modes, offering a battery life of 8-12 hours. The efficient power system is equipped with high-torque motors and variable frequency control technology, adapting to complex environments such as ramps and rough roads.

Safety Design: Includes hydraulic braking, electronic parking, overload alarms, anti-collision sensors, etc. It has synchronous operation capability for heavy cargo.

Flatbed transfer carts: Highly versatile, with optional guardrails or fixtures.

Rail transfer trolley: Used for fixed routes (such as workshop tracks).

Application Scenarios:

Manufacturing: Transporting large machinery, molds, steel, etc.

Logistics and warehousing: Moving containers and heavy-duty shelves.

Ports and terminals: Collaborating with lifting equipment for cargo handling.

Special industries: Transportation of oversized cargo like wind turbine blades and transformers.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.