Get a Quote

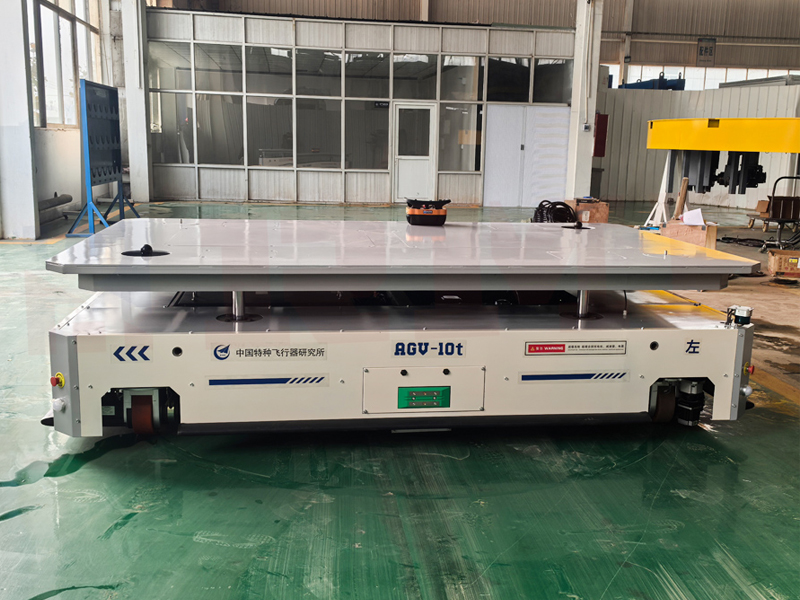

AGV is an intelligent transportation tool equipped with automatic guiding devices such as electromagnetic or optical ones. It can automatically travel along a preset path and perform material handling tasks. The AGV automatic transport cart uses a battery as its power source and does not require manual driving. Its driving path and behavior are precisely controlled by a computer system. It has a highly advanced safety protection mechanism and diverse cargo-carrying functions. The heavy-duty AGV can be customized to have a load capacity ranging from 1 to 200 tons, and it can adapt to various handling requirements. It is widely applied in fields such as manufacturing, warehousing, and supply chain management. It can effectively improve work efficiency, reduce the demand for manpower, and enhance operation accuracy and safety.

Features and Advantages of AGV Automated Transport cart

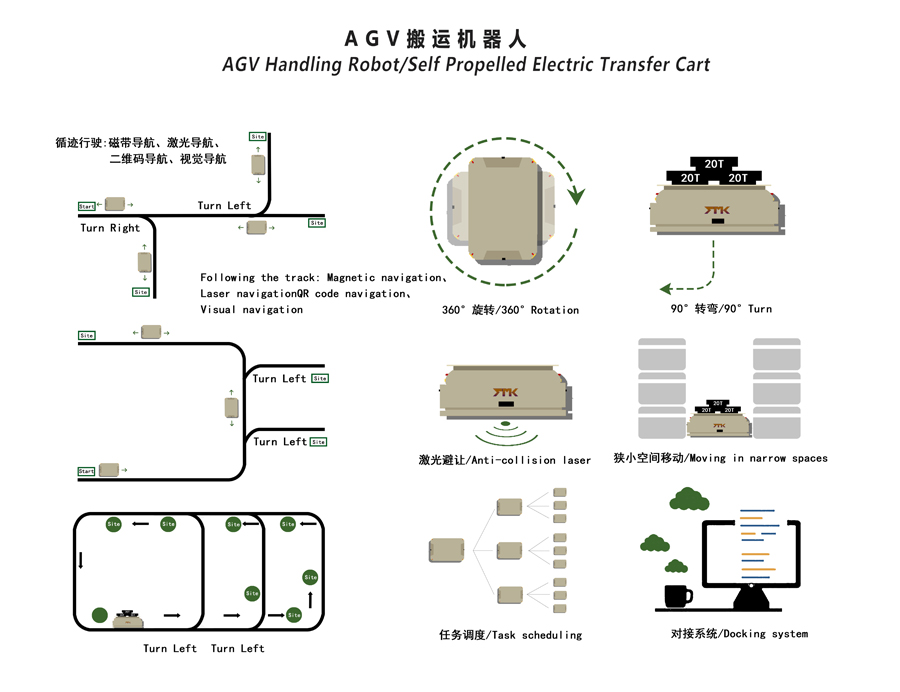

Driverless: It can automatically complete the material handling task without manual intervention.

Guided Mode: It usually travels along the preset paths, which can be realized through various means, such as magnetic tape, laser, vision, QR code, etc., or adopt a hybrid navigation mode of more than two of these methods simultaneously.

Intelligent Scheduling: Based on an advanced scheduling system, it can quickly change the driving route and handling tasks, and respond to the changes in handling requirements in real time.

Automatic Charging: It will automatically charge when the battery level is low to ensure continuous operation for 8×24 hours.

Safety Protection: It is equipped with multiple safety devices to ensure safety during driving and prevent collisions with people or other objects.

Customization: According to different application scenarios and requirements, there are multiple models available for selection, and it can be customized according to specific needs.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.