Electric transfer carts are increasingly powered by green and eco-friendly batteries. Battery-powered transfer carts have become the mainstream of material handling equipment, except for special working conditions where battery power is not feasible. Just like our mobile phones and new energy vehicles, battery-powered transfer carts require chargers, and their huge advantage lies in rechargeable and cyclic use. So how to

select a suitable charger for battery transfer carts?

We need to comprehensively consider the following key factors based on the specific model of the electric flat cart, battery type, charging requirements, budget and other aspects:

Battery and Trolley Characteristics

First of all, verify whether the output voltage and current range of the charger are fully matched with the rated voltage and capacity of the battery pack of your Battery transport cart. Different batteries (e.g., lead-acid, lithium-ion) have distinct charging curves, and a high-quality charger should be adaptable to them.

On-site Working Conditions and Environment

Environmental Conditions

If the transfer trolley operates in a humid, dusty or corrosive environment, priority should be given to chargers with a high protection rating (e.g., IP65 or above) or contactless wireless charging solutions to ensure operational safety and equipment service life.

Operational Rhythm

If the battery transfer trolley needs to run 24/7 without interruption, fast charging or automatic charging solutions (e.g., wireless charging) can effectively utilize short downtime for recharging and maximize vehicle utilization efficiency.

Space and Layout

For sites with limited space or scenarios requiring centralized charging for multiple carts, modular, stackable charging systems or distributed small charging piles are recommended.

Cost and Efficiency

Advanced solutions such as wireless charging involve a higher initial investment, but they can save labor costs, reduce component wear and tear, and cut down maintenance expenses. You need to make a comprehensive trade-off based on the expected usage intensity, labor costs and long-term operational efficiency.

| Charger Type | Key Features | Applicable Scenarios & Notes |

Wired/Contact Charger | Requires physical connection (plug or charging gun). Mature technology, widely used. | Suitable for most fixed charging points within facilities, such as overnight parking areas. Requires manual or robotic plugging/unplugging. |

Wireless/Inductive Charger | No physical contact; energy transfer via magnetic fields. High water/dust resistance, enhanced safety. | Ideal for AGVs (Automated Guided Vehicles), harsh environments (humid, dusty), or scenarios requiring fully automatic charging. |

On-board Charger | Installed on the transporter, can be directly connected to AC power to charge the vehicle's battery. | Common for transfer carts needing external AC power top-up, offering convenience and flexibility. |

Fast/High-Power Charger | High power output enables rapid battery top-up, minimizing downtime. | Suitable for electric flatbed cars or port tractors with high operational continuity requirements and large battery capacities. |

Portable/Mobile Charging Unit | Flexible and movable, no fixed installation required. Can serve as an emergency or temporary charging solution. | Suitable for sites with dispersed work points, no fixed charging piles, or insufficient power infrastructure. |

How to Make a Decision for Your Factory's Transport Flatbed Carts

You can follow this line of thinking:

Assess Operational Model:

If your transport work is batched with clear intervals (e.g., lunch breaks, after shifts) available for centralized charging, then traditional wired/contact chargers are perfectly adequate and offer the best cost-effectiveness.

If it's for assembly line coordination, requiring the transfer trolley to shuttle almost continuously, then automatic fast charging or wireless charging capable of utilizing brief stops (e.g., 1-2 minutes during loading/unloading) for top-up becomes the ideal choice to ensure continuous production.

Inventory On-site Conditions:

Environment: Does the workshop have metal dust, moisture, or corrosive gases? If yes, wireless charging or high ingress protection (IP65) wired charging piles are essential.

Space: Is the charging area fixed and spacious? Is it convenient for drivers to park and plug/unplug? For tight spaces, wall-mounted or flush-mounted wireless charging transmitters save more space.

Power Grid: Does the planned installation location for the charging pile have sufficient electrical capacity? High-power fast charging requires separate calculation of circuit load.

Calculate Long-term Costs:

Don't just look at the unit price of the equipment. Consider labor costs for operation, downtime costs during charging, and maintenance costs for connector replacement. For intensive, three-shift transport operations, wireless charging, while potentially more expensive upfront, may lead to lower total cost of ownership.

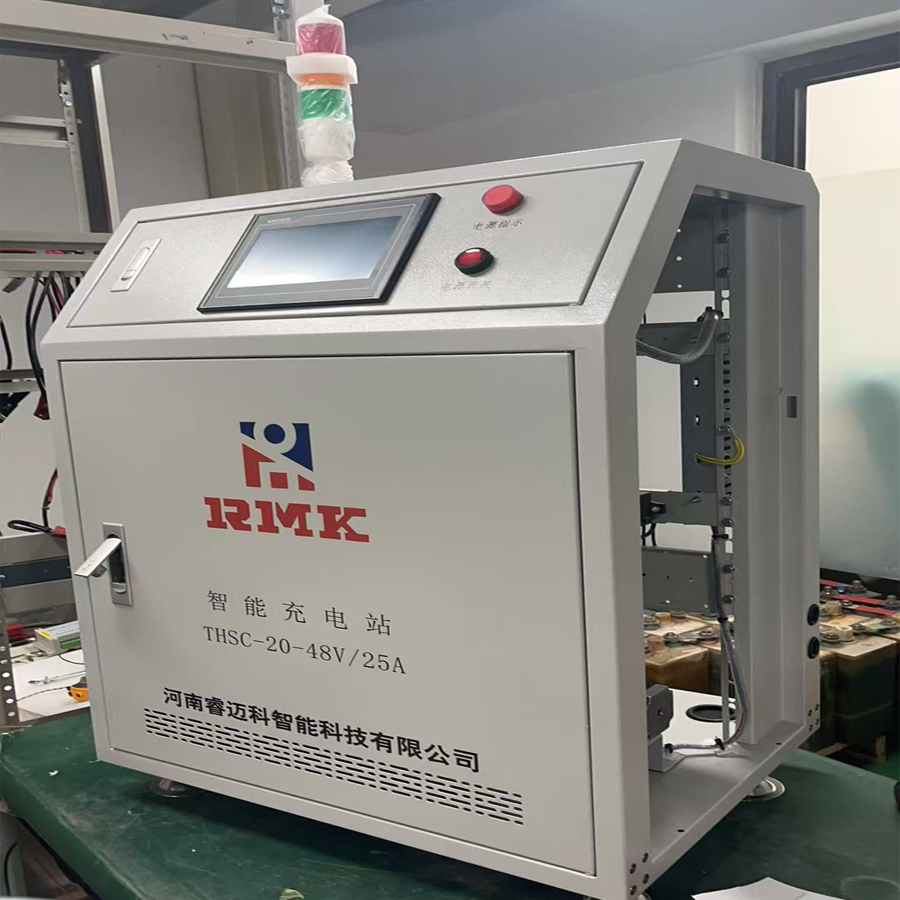

Core Parameters & Brand Selection Suggestions

Once the general solution type is determined, be sure to confirm the following technical details:

Voltage/Current Compatibility: The charger output must be 100% compatible with your flatbed car's battery pack voltage (e.g., 48V, 72V) and capacity.

Charging Algorithm: A quality charger should feature multi-stage intelligent charging (e.g., constant current, constant voltage, float charge), which is crucial for extending the lifespan of lead-acid or lithium batteries.

Ingress Protection (IP) Rating: An IP rating of at least IP54 (dust and water splash resistant) is recommended for factory environments. Harsher environments may require IP65 or higher.

Communication Interface: Chargers supporting CAN Bus communication can "talk" to the vehicle's Battery Management System (BMS), enabling more precise management and protection.

Humanistic Customized

Humanistic Customized