Get a Quote

This 15 tons Battery powered steel coil rail transfer cart is fully automated, capable of loading and unloading steel coils at different workstations, crossing the cross track and working continuously according to the set operating track. When the battery is low, it can automatically recharge. In addition, this rail car also has hydraulic lifting function, which is convenient for docking with steel coil racks. There are some protective devices designed on the cart,such as alarm light, emergency stop button, laser scanning sensor.

Main technical specifications about heavy load battery powered track transporter:

Load capacity: 15 tons

Table size: 3*2.2*1m

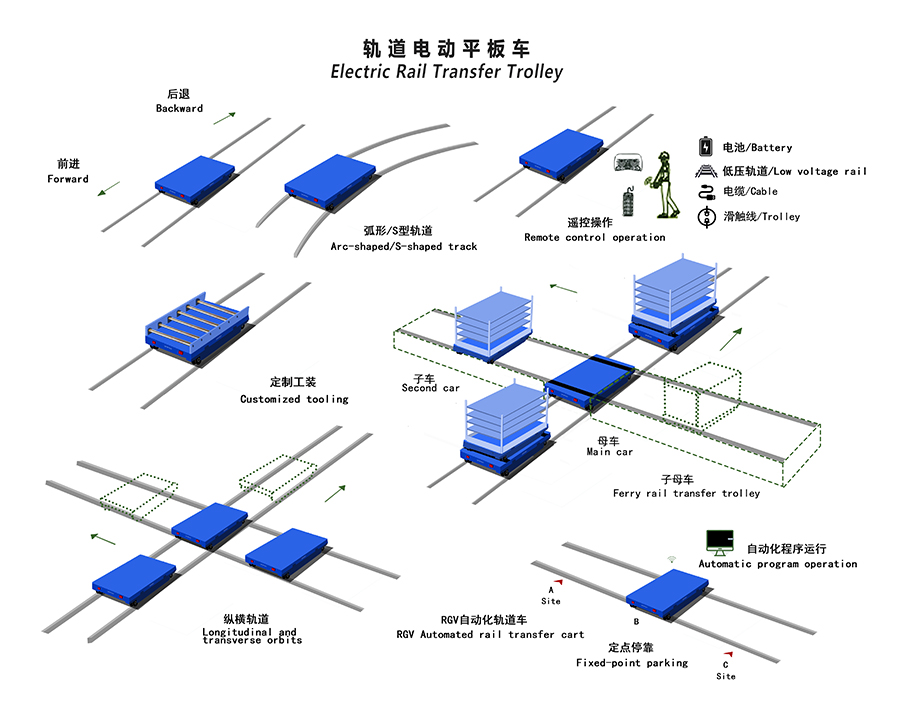

Operate mode: automatically or remote control

Speed:0-20m/min

Painting color: it can be customized

Brake: electromagnetic brake

Move way: forward, backward, move sideways

Core function description of heavy-duty longitudinal and transverse mobile steel coil track transfer vehicle

1. Fully automated operation: It can automatically load and unload steel coils at different workstations, cross cross cross tracks, and operate continuously according to preset tracks. When the battery is low, it can automatically go to charge.

2. Hydraulic lifting function: Equipped with a hydraulic lifting system, it can flexibly adjust the height, facilitate precise docking with steel coil racks, and improve loading and unloading efficiency.

Advantages of Vertical and Horizontal Mobile Rail Transfer Cart Design

-High space utilization: It can move along intersecting tracks, breaking the limitations of a single track, and can flexibly shuttle within narrow or complex layouts without the need for additional large turning spaces.

-Outstanding homework efficiency: Combining automated operation (such as preset paths, automatic charging) with hydraulic lifting and other functions, reducing manual intervention, achieving multi station continuous transportation, and shortening loading and unloading and transportation cycles.

-Strong load-bearing capacity: The body structure is designed for heavy loads and can stably carry heavy goods such as steel coils, molds, and heavy components. It has high stability during operation and reduces the risk of cargo damage.

-Flexible adaptability: The track layout, load-bearing capacity, and supporting functions (such as installing positioning devices and safety protection systems) can be adjusted according to the needs of the scene, adapting to different sites and types of goods.

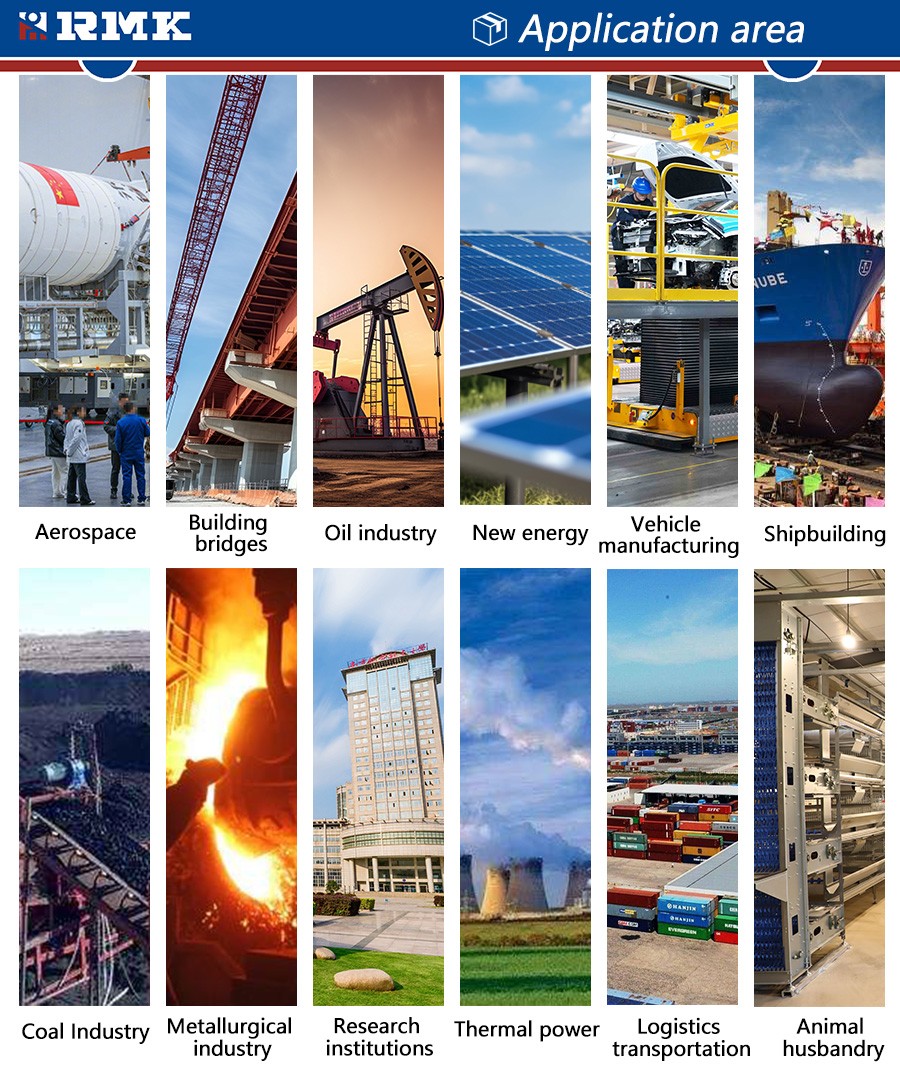

Main application areas of heavy-duty rail transport platform

-Steel metallurgy industry: used for cross workshop and cross station transportation of heavy steel materials such as steel coils, billets, and sections, connecting with steel rolling, warehousing, processing, and other links to achieve automation of steel circulation.

-Heavy manufacturing industry: In the production of engineering machinery, ships, rail transit equipment, etc., it transports large components (such as machine tool beds and ship sections) to meet the material handling needs of heavy production lines.

-In the field of warehousing and logistics, precise transportation of goods between different shelves, storage areas, or transportation equipment (such as trucks and cranes) is achieved in scenarios such as heavy-duty three-dimensional warehouses and port freight stations, improving warehousing turnover efficiency.

-Chemical and Energy Industry: Used for transporting heavy goods such as large chemical storage tanks and energy equipment accessories. With special customization for explosion prevention and corrosion resistance, it can adapt to high-risk or harsh working environments.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.