Get a Quote

Introduction to 40 ton steel structure track transfer trolley:

1. Composition structure: It consists of a cable reel powered track car and an unpowered track car.

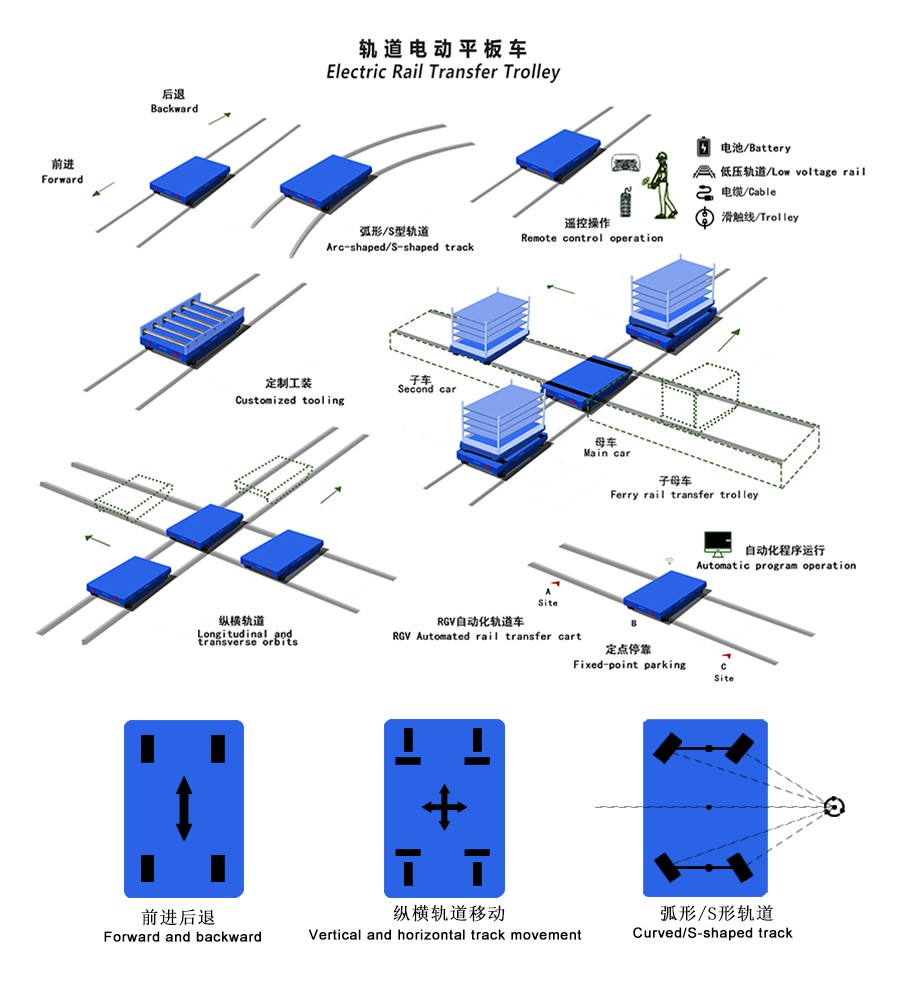

2. Material transfer: It can transfer steel coils, steel plates, steel pipes, molds, steel billets, etc.

3. Power supply method: The standard configuration is cable reel power supply, with optional battery power supply, sliding contact line power supply, and low-voltage track power supply.

4. Safety protection: equipped with emergency stop button, alarm light, limit switch, laser obstacle avoidance sensor and other devices.

Main technical specifications about heavy duty track transfer trolley:

Load capacity: 40 tons

Table size: 7200*2200*900mm

Power supply mode: cable reel power supply, with optional battery power supply, sliding contact line power supply, and low-voltage track power supply

Operate mode: wireless remote control+hand pendant

Speed: 0-20m/min

Painting color: Full yellow, it can be customized.

Design advantages of heavy-duty track transport platform:

1. Strong load-bearing capacity: With a sturdy structure (such as a steel frame), it can stably carry heavy materials (such as tens of tons of steel coils and billets), meeting the heavy industry's heavy-duty transportation needs.

2. Stable and reliable operation: Traveling along a fixed track, the path is precise, and there will be no deviation or slipping problems, ensuring the smoothness of material transportation and reducing cargo collision losses.

3. Adapt to various scenarios: support multiple power supply methods such as cable reels and batteries, and can be flexibly selected according to workshop layout and power supply conditions, adapting to different industrial environments (such as intra workshop and cross regional transportation).

4. High safety: Equipped with multiple protective devices such as emergency stop button, laser obstacle avoidance, and limit switch, it can respond to emergencies in a timely manner and avoid safety risks such as collisions and overtravel.

5. Easy to operate: It can achieve manual or semi-automatic control, with simple operation logic, reducing the difficulty of manual operation; Part of it can be linked with the production line to improve the efficiency of automated transportation.

6. Excellent space utilization: It runs linearly along the track, without the need to reserve large turning or avoidance spaces, especially suitable for dense transfer scenarios with narrow passages and multi station connections in the workshop.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.