Get a Quote

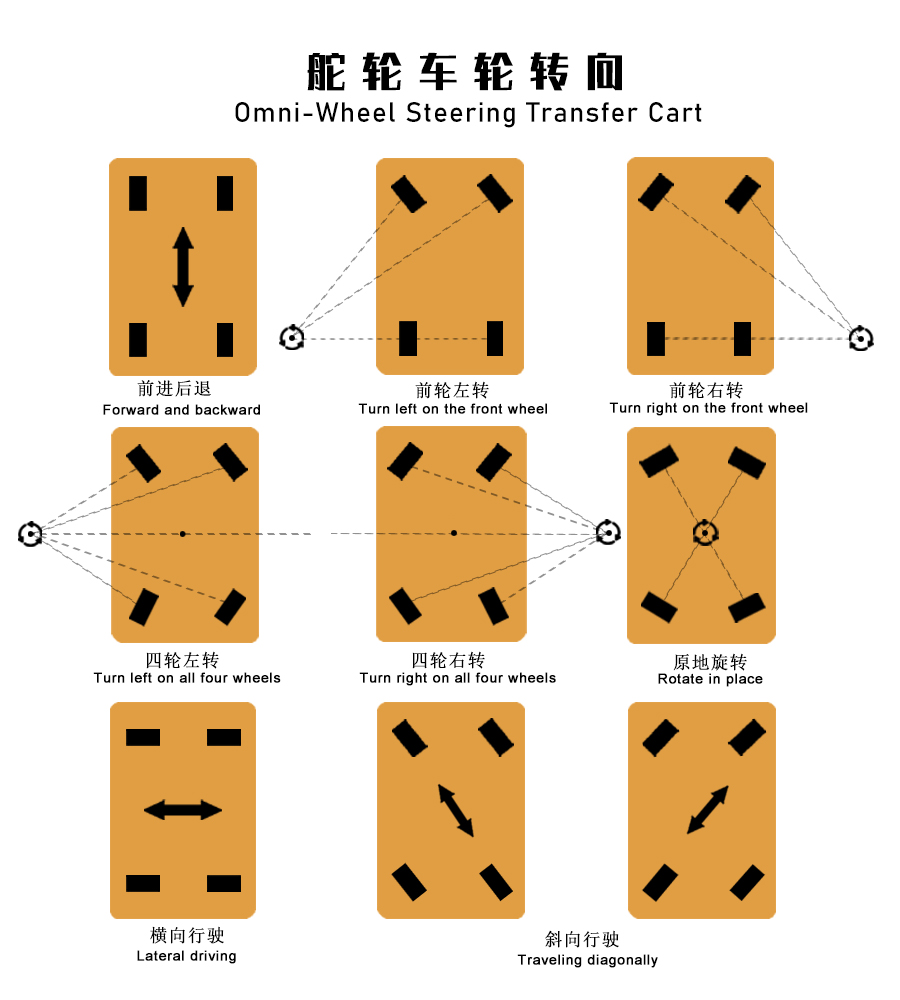

We have carefully designed a 50 Tons Mold Omni-directional Battery Trackless Transfer Cart for our Saudi customer, which is equipped with two sets of battery packs and can meet continuous use for 5 hours. Maintenance free lead-acid battery omnidirectional trackless transport platform can move forward, backward, turn while walking, rotate 360 degrees in place, move horizontally and vertically, and tilt. It can also meet a slope of 5 degrees when fully loaded, and hydraulic lifting function is designed according to customer needs. The lifting stroke can be customized according to customer requirements.

Main technical specification about heavy load 50 tons omni-directional transfer trolleys:

Load capacity: 50 tons, it can be customized according to different clients' different requirements

Table size: 8*3*1m

Power supply mode: Maintenance-free lead-acid batteries

Operate mode: wireless remote control+ hand pendant

Speed:0-20m/min

Brake: Electromagnetic brake

Painting: Full Yellow, it can be painted according to customer requirement.

Protective devices: alarm light, emergency stop button, laser scanning sensor

Other function: hydraulic lifting stroke of 300mm

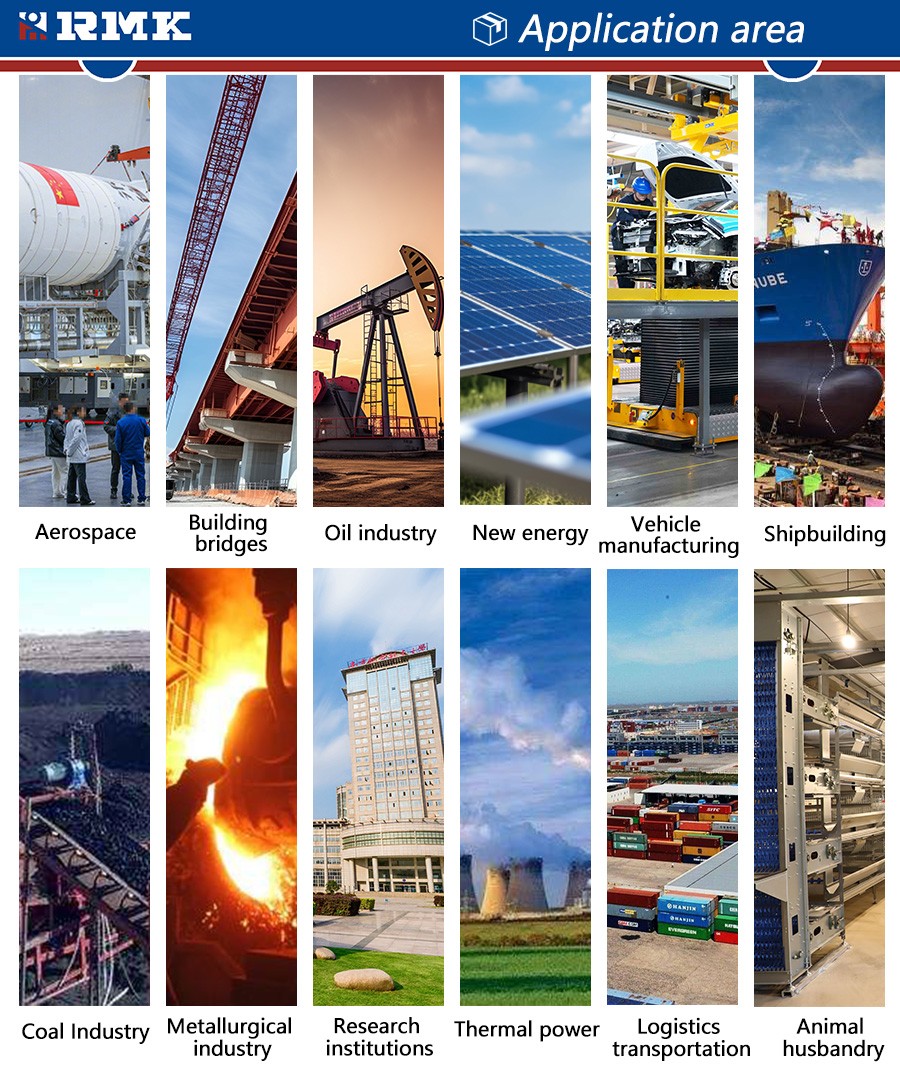

Omnidirectional battery transporter have a wide range of applications due to their flexible omnidirectional mobility, heavy load capacity (some models), and adaptability to complex fields, mainly including the following categories:

-Industrial manufacturing: such as automobile production workshops, used for handling large vehicle bodies, engines, and other components; In heavy machinery manufacturing, transporting large molds, frames and other heavy equipment can move accurately in narrow workshops.

-Warehouse logistics: In high shelf warehouses and dense storage areas, it is possible to flexibly shuttle between shelves to complete the retrieval, storage, and transportation of goods, especially suitable for scenarios with limited space.

-Ports and airports: used for short distance transfer of port containers, rapid handling of airport luggage or cargo, and can adapt to the needs of multi-directional operations within the site.

-Special industries: such as the military industry, transporting weapons and equipment, and large equipment; In the field of new energy (such as photovoltaics and wind power), handling large components or heavy fixtures, some models can meet special needs such as climbing and customized lifting.

The design advantages of heavy-duty omnidirectional trackless transfer carts are mainly reflected in flexibility, adaptability, efficiency, and safety, as follows:

1. Omnidirectional movement, extremely flexible

With the help of omnidirectional wheels or special drive structures, it is possible to achieve all-round movements such as forward, backward, lateral movement, and stationary rotation, without the need for reserved steering space. It can flexibly shuttle in narrow areas such as workshops and warehouses, especially suitable for complex layout scenarios.

2. Trackless design, wider adaptability

-Get rid of track restrictions, no need to lay tracks or rails, can operate on ordinary ground (cement, asphalt, etc.), and can quickly switch work areas

3. Heavy load capacity and high load-bearing efficiency

-In terms of design, it can meet the transportation needs of large tonnage goods (ranging from tens to hundreds of tons), replace traditional cranes, forklifts and other equipment, and improve the stability of heavy-duty transportation.

4. Modular design for easy maintenance

-The core components such as drive and transmission often adopt modular structures, which are easy to disassemble and replace

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.