Get a Quote

4

Türkiye customers have purchased two trackless transfer carts from our company, one is a 5-ton load differential steering trackless transporter, and the other is a 40 Tons Hydraulic Turning

Mold Transport Platform . This 40 ton mold transfer trolley can move forward, backward, and turn while walking, running smoothly and safely. In addition, it is equipped with some safety protection devices, such as sound and light alarm lights, emergency stop buttons, and laser obstacle avoidance sensors. Added some safety measures for customers when using and operating transporter.

Procurement list and core parameters of trackless transfer carts for customers in Türkiye

1. 5-ton trackless transfer vehicle: The core configuration is differential steering, suitable for flexible transfer needs in medium load scenarios.

2. 40 tons heavy-duty mold transfer vehicle (core equipment):

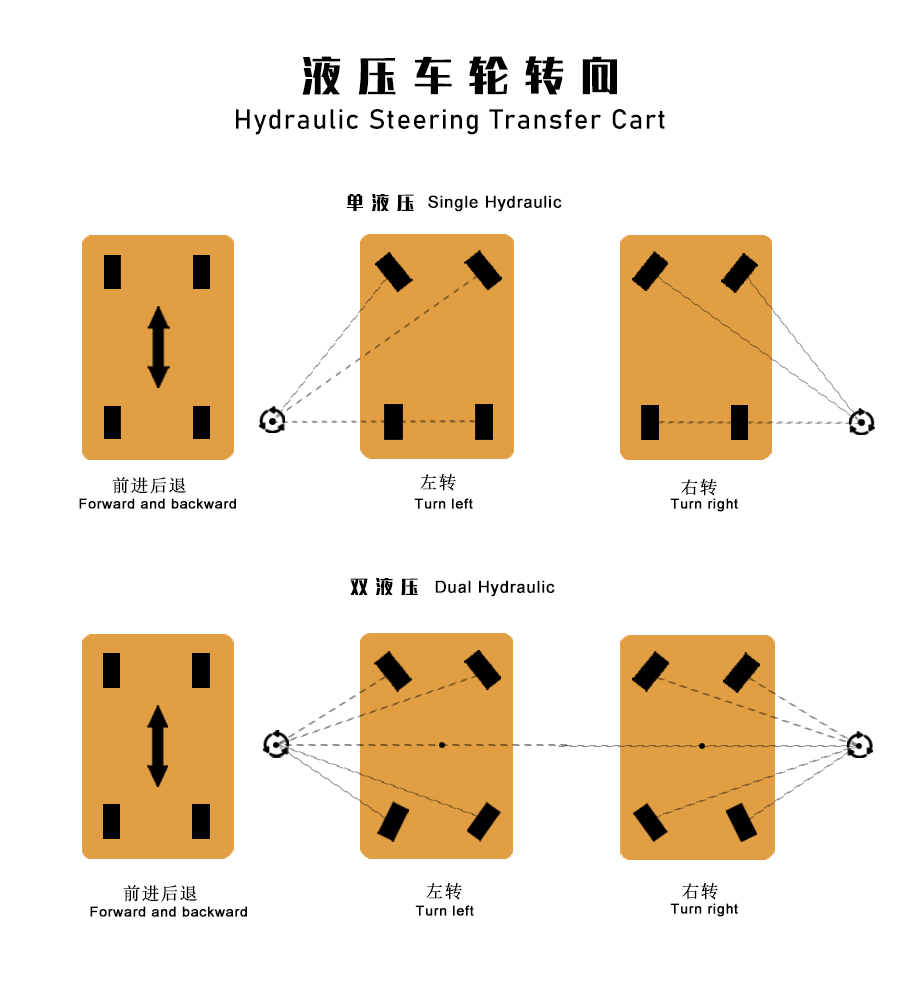

-Steering mode: single hydraulic steering, suitable for steering stability under heavy load conditions.

-Core function: Supports forward and backward movement, and can achieve "turning while walking", balancing smooth and safe operation.

-Safety protection device:

-Sound and light alarm light (warning the surrounding environment during operation)

-Emergency stop button (quickly cuts off operation in case of emergency)

-Laser obstacle avoidance sensor (actively detecting obstacles and avoiding risks in advance) ensures multi-dimensional operation and use safety.

Main technical parameters about heavy load die transport platform:

Load capacity: 40 tons

Table size: 4000*2000*900mm

Power supply mode: lead acid battery

Speed: 0-20m/min

Move day: move forward, backward, turning while in moving without any stop

Brake: electromagnetic brake

Operate mode: remote control+hand pendant

Painting color: Blue+gray

The heavy-duty hydraulic steering trackless transfer carts, with its strong load-bearing capacity and stable steering characteristics,

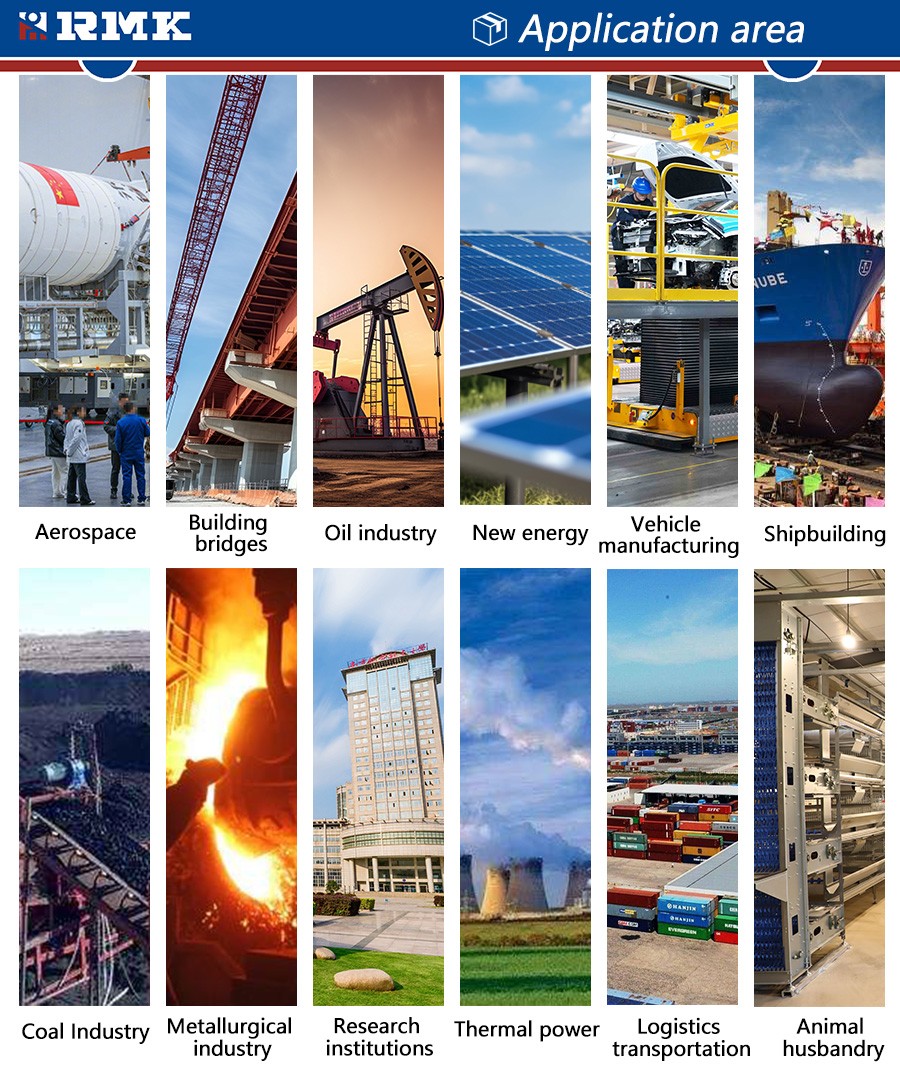

is mainly suitable for the following heavy industrial fields to meet the transportation needs of heavy materials/equipment:

-Steel mill: used for the transportation of heavy steel such as steel coils and billets in the workshop.

-Mold industry: precise handling and positioning for large molds (such as automotive stamping molds).

-Metallurgical plant: adapted to the circulation of heavy loads such as metallurgical raw materials and smelting equipment.

-Paper manufacturing plant: transporting large-sized paper rolls and heavy-duty papermaking equipment components.

-Automobile manufacturers: handling heavy components such as car chassis and large body frames.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

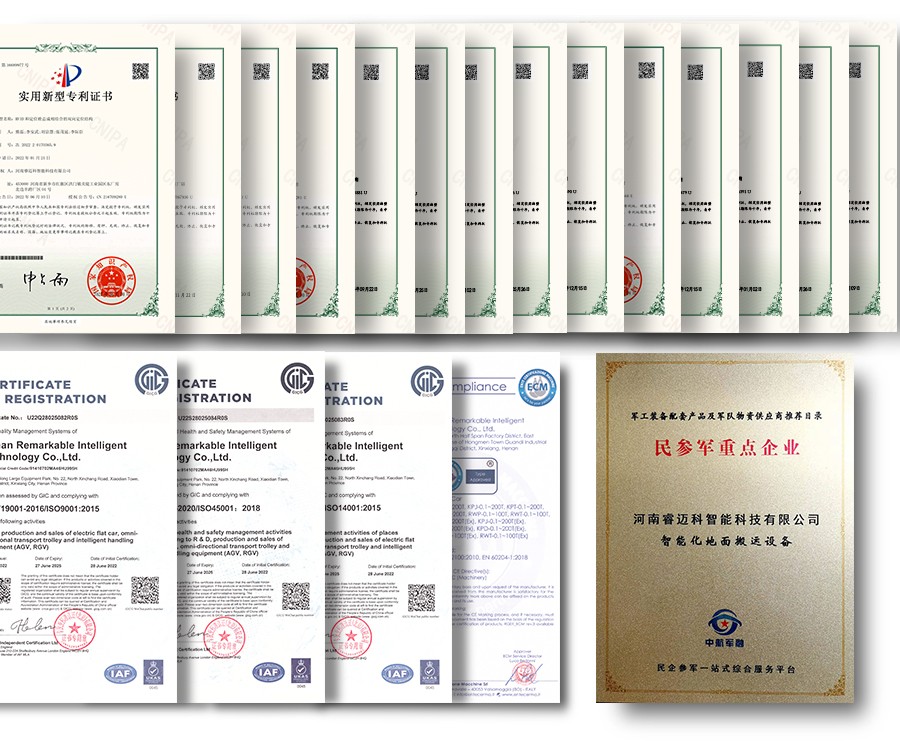

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.