Get a Quote

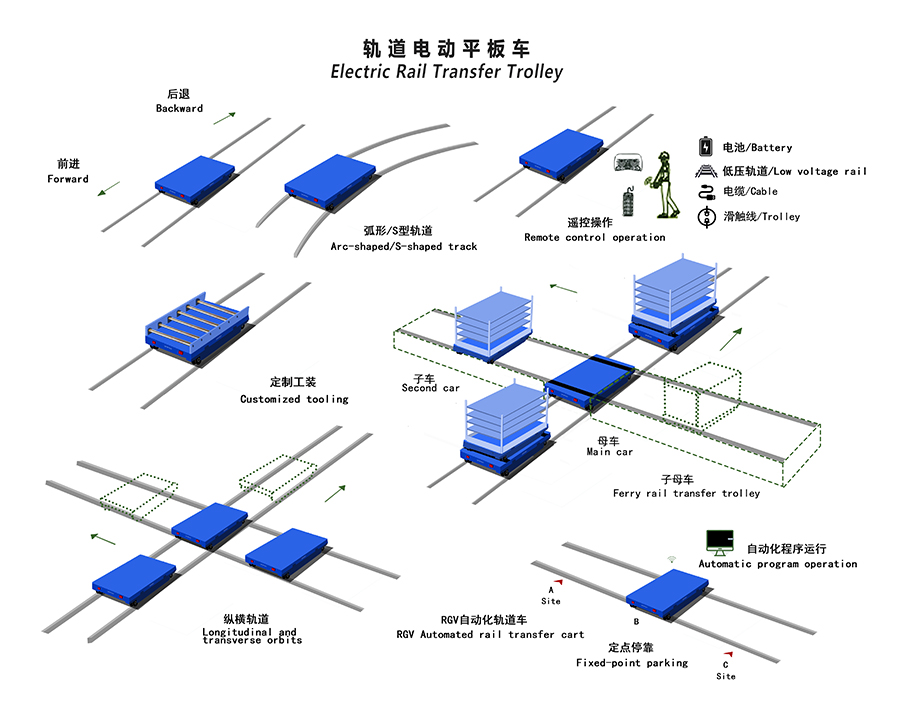

Automated rail transfer carts are automated handling equipment that operate on pre-set tracks. They can integrate various additional functions based on the trolley, such as forklift functions, manipulator functions, roller conveying functions, coil saddle functions, etc. This enables the transfer cart to have autonomous loading and unloading capabilities, significantly improving productivity. It can achieve precise material access, cross-regional transportation, and automated docking in complex industrial scenarios, serving as the core link connecting warehousing, production lines, and logistics.

RGV rail transfer trolleys support modular design. The lifting height, load capacity (1-5 tons), and arm length can be customized according to the scenario, and the track layout can be flexibly adjusted to meet the upgrading needs of factories.

Application Scenarios of Forklift Arm Rail trolley (RGV)

The forklift arm-type automated rail guided vehicle (RGV) can achieve unmanned pallet handling, replacing manual forklifts, and automatically complete pallet lifting, fork taking, stacking, and handling.

Heavy-duty Component Handling: For large workpieces in industries such as automobile manufacturing and mechanical processing, the forklift arm-type RGV can stably carry several tons of goods to ensure safe transportation.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

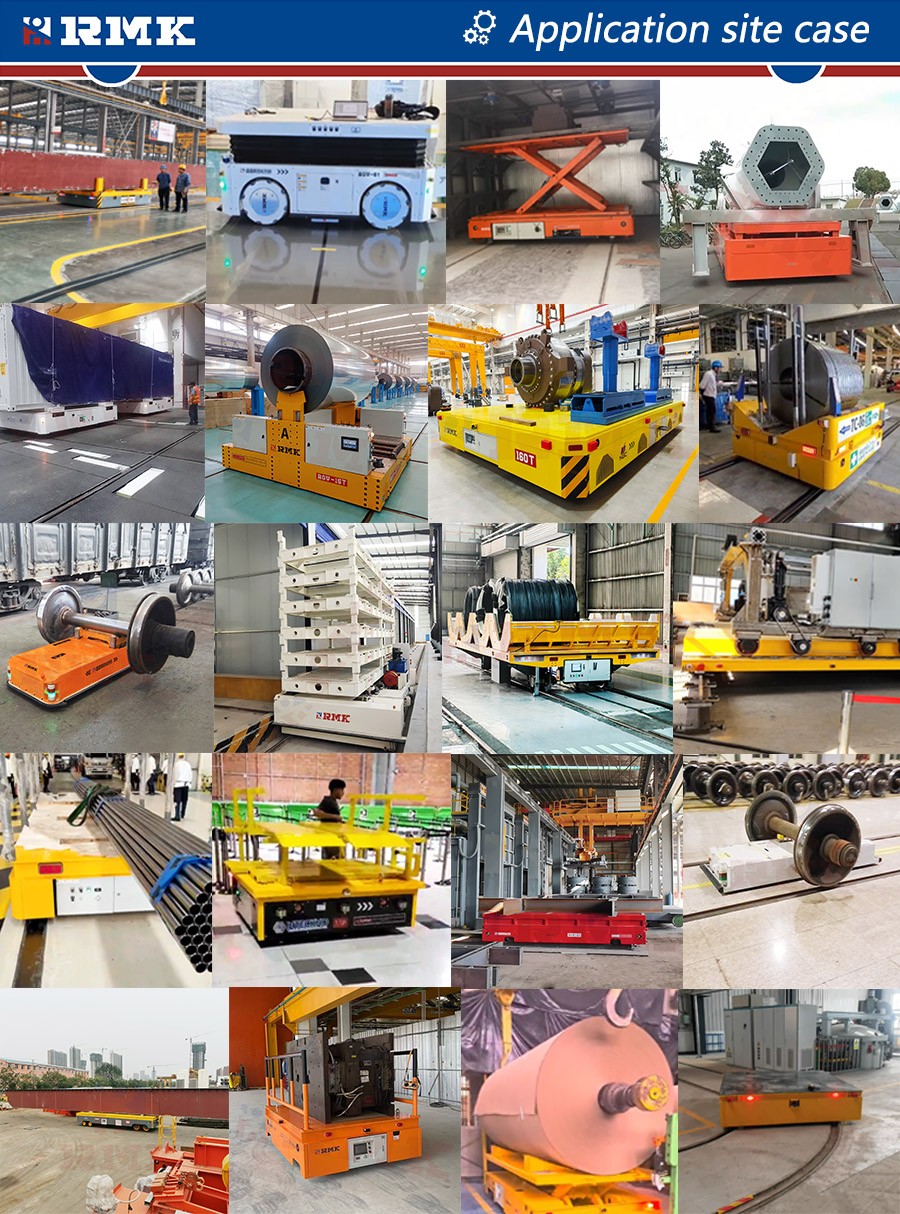

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.