Get a Quote

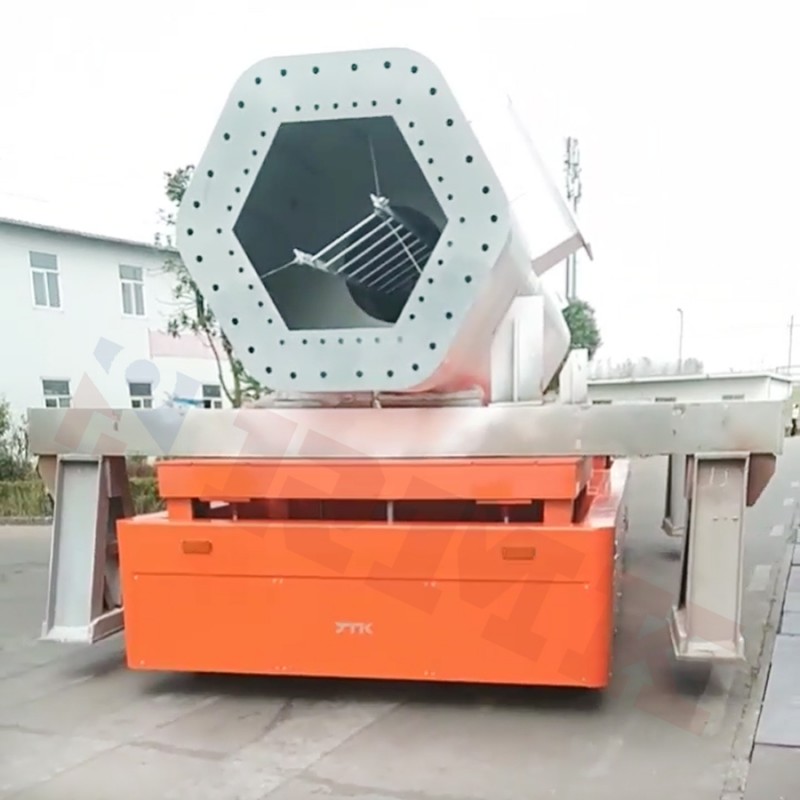

The 60 Tons Transformer Battery Transfer Cart designed by Henan Remarkable has a large platform, so in order to make the turning and running process smoother, we chose dual

hydraulic steering. In addition, we also designed local hydraulic lifting at both ends of the platform. Each end of the table is controlled by an electronic valve that controls four hydraulic

cylinders. The hydraulic steering and hydraulic lifting share a hydraulic system, which effectively solves the customer's usage needs.

Main technical specification about heavy duty trackless transporter:

1. Load capacity: 60T

2. Table size: 7*3*1m

3. Power supply mode: lead acid battery or lithium battery

4. Operate mode: wireless remote control + hand pendant

5. Speed: 0-50m/min

6. Protective measure:Sound and light alarm light, emergency stop button, laser obstacle avoidance

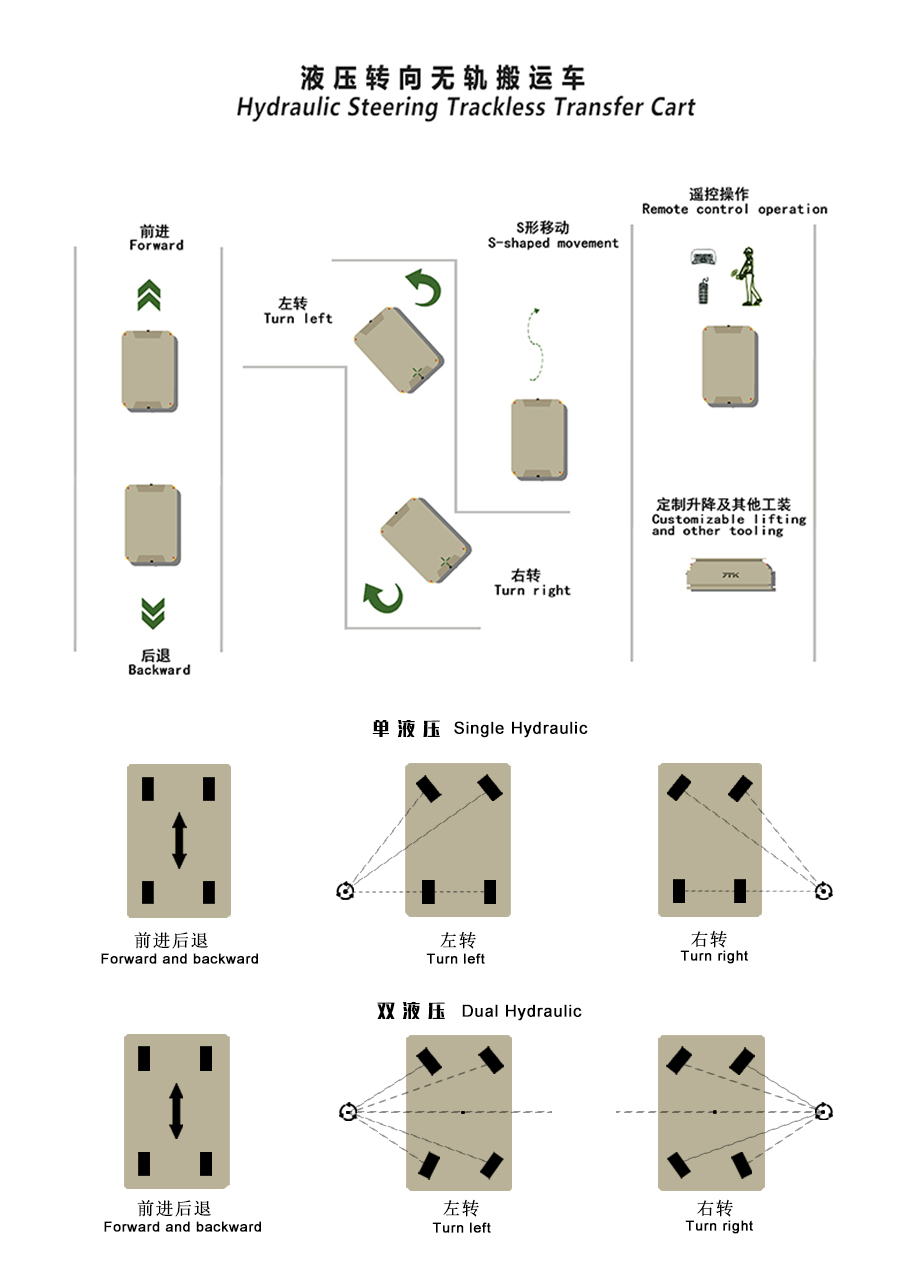

Design Features of Hydraulic Steering Trackless Vehicle:

-Accurate and flexible steering: hydraulic transmission responds quickly, stable power assistance, and can achieve small turning radii

-Strong load-bearing capacity: The hydraulic system has high power density and can be matched with heavy-duty frame designs to meet the transportation needs of heavy materials.

-Lightweight and effortless control: Hydraulic power assistance reduces steering resistance, combined with a user-friendly operation layout

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.