Get a Quote

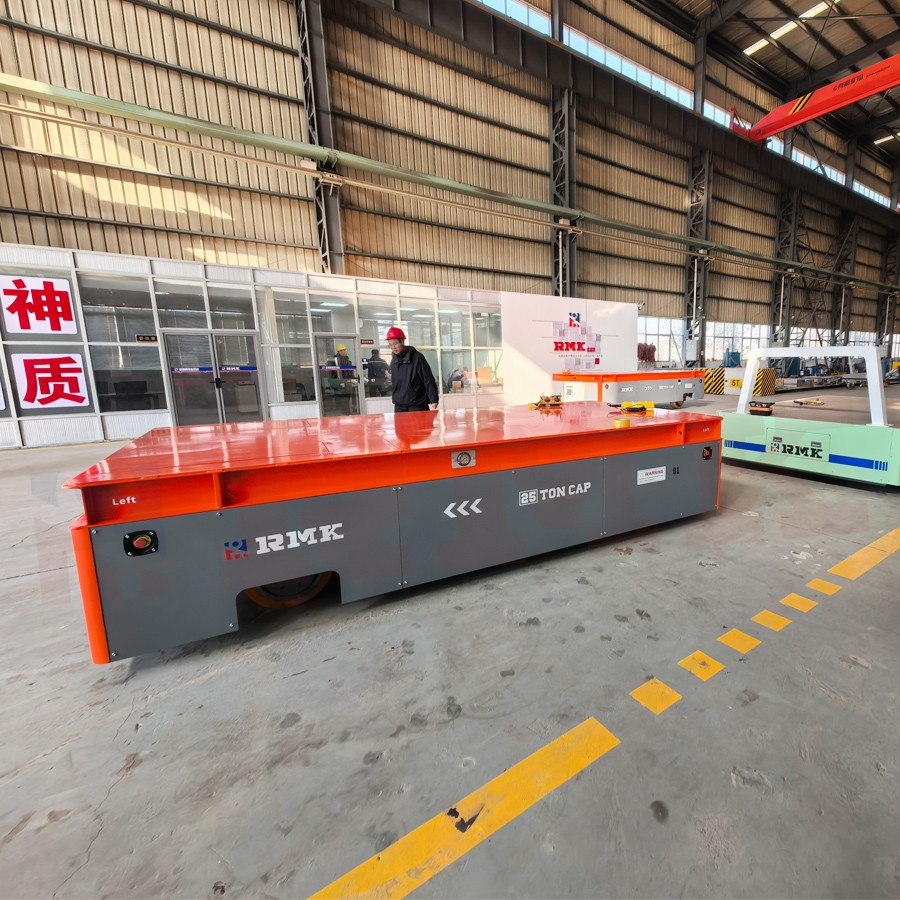

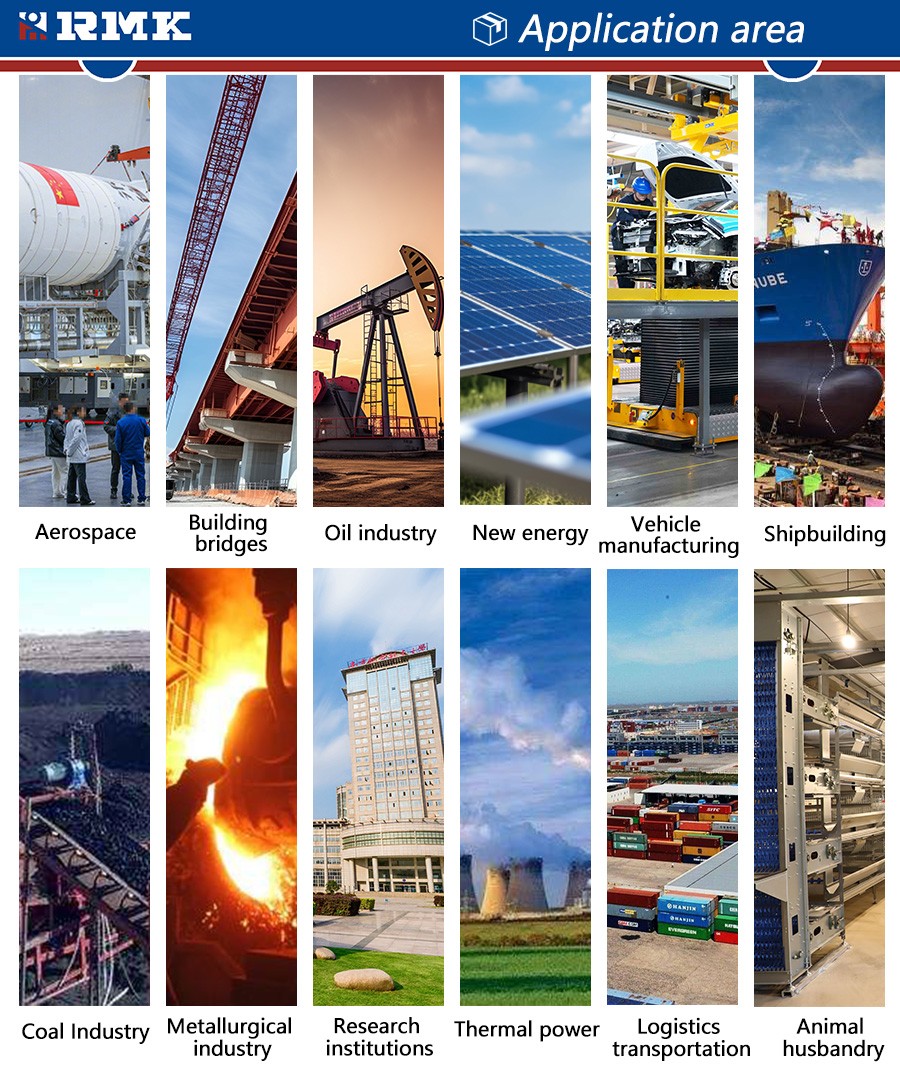

The Heavy load 25 Tons Battery Lifting Trackless Transfer Cart is Customized For American Customer By Henan Remarkable Can Move Forward, Backward, Turn Left, Turn Right, Rotate 360 Degrees Left And Right, And Turn While Walking. The Power Supply Method Can Be Lithium Battery Or Lead-Acid Battery, Which Is Convenient For Customers To Inspect And Maintain. We Have Designed The Entire Platform Lifting For These Two Vehicles. Heavy Duty Railless Vehicles Are Suitable For The Transportation Of Concrete Structural Components, Metallurgical Industry, Mold Transportation, Shipyard, Aerospace, Military Factory Material Transportation, Etc. We Can Carefully Design And Customize Products According To Customer Needs. There Are Also Emergency Stop Buttons, Warning Lights, Etc. Installed To Ensure That In Case Of An Emergency, The Emergency Stop Button Can Be Pressed To Quickly Stop The Cart.

Main Technical Parameters About Battery Powered Trackless Transfer Carts:

Model:RWP-25T

Table Size(mm):4000*2000 *900

Wheel Material:Polyurethane Rubber Coated Wheel

Power Supply Mode: Maintenance-Free Lead-Acid Battery

Operate Mode: Remote Control+Hand Pendant

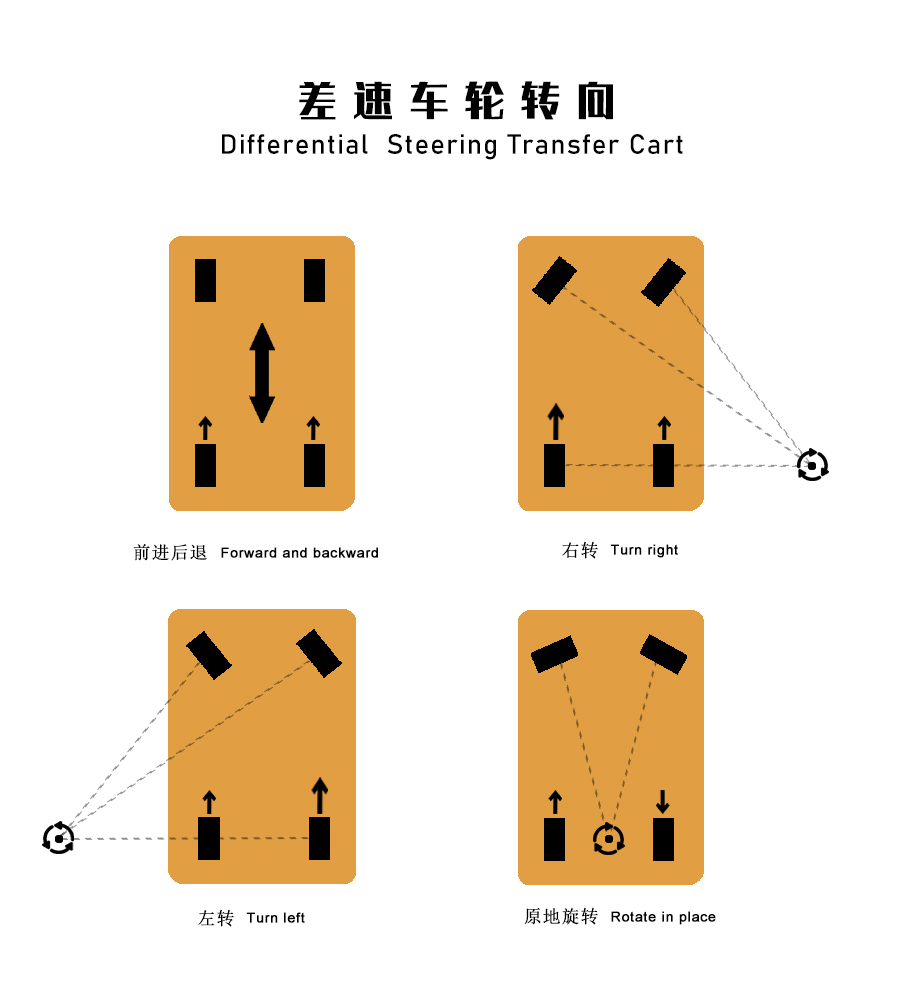

Differential steering trackless transporter operation mode

The core of differential steering railless vehicles is to achieve steering through the speed difference between the left and right driving wheels, without the need for steering wheels. It is suitable for heavy load and low-speed working conditions and is the mainstream solution for industrial heavy-duty transportation.

1. Drive in a straight line

The left and right drive wheels move at the same speed and direction, and the vehicle moves in a straight line, making it suitable for long-distance transportation.

2. Arc turning (non-zero radius)

The left and right wheels move in the same direction at different speeds, with the inner wheel being slower and the outer wheel being faster. They perform circular motions around the ICR, adapting to channel turns and workstation adjustments.

3. Turn in place (zero radius)

The left and right wheels are in constant speed and reverse direction, with the ICR located at the center of the vehicle, achieving a 360 ° stationary turn and efficient steering in a very small space.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.